Author: Denis Avetisyan

Researchers are combining atomistic simulations and machine learning to pinpoint the microscopic factors governing the strength of complex, high-temperature alloys.

This study details a multi-faceted approach to understanding and predicting local slip resistance in refractory multi-principal element alloys, offering insights into thermally activated yield strength.

Despite their promise for high-temperature applications, the complex compositions of refractory multi-principal element alloys hinder a fundamental understanding of plastic deformation mechanisms. This research, titled ‘Atomistic and data-driven insights into the local slip resistances in random refractory multi-principal element alloys’, combines atomistic simulations and machine learning to reveal the relationships between alloy composition, local slip resistance of dislocations, and macroscopic yield strength. Specifically, we identify elastic constants and lattice distortion as dominant factors controlling dislocation glide, enabling accurate prediction of tensile yield stress in these materials. Can this framework guide the rational design of next-generation refractory alloys with optimized high-temperature performance?

The Inevitable Complexity of Alloy Design

Traditional alloy development frequently encounters performance plateaus stemming from inherent limitations in compositional space and the tendency for elements to segregate or form secondary phases. As the number of constituent elements increases in conventional alloys, the resulting phase diagrams become exceedingly complex, often restricting the formation of stable, single-phase solid solutions. This limited solubility restricts the ability to fully exploit synergistic effects between elements, hindering improvements in mechanical properties like strength and ductility. Furthermore, the presence of even small amounts of secondary phases can act as stress concentrators, significantly reducing overall material toughness and reliability; thus, pushing the boundaries of alloy design requires overcoming these restrictions imposed by compositional complexity and the constraints of solid solution limits.

Conventional alloys frequently encounter performance plateaus due to the inherent restrictions of compositional complexity and limited solubility ranges. Refractory multi-principal element alloys (RMPEAs) present a compelling alternative, circumventing these limitations through the deliberate maximization of compositional entropy. By introducing multiple principal elements in near-equal atomic proportions, RMPEAs create a highly disordered solid solution, effectively suppressing the formation of brittle intermetallic phases and broadening the range of stable solid solutions. This approach not only enhances alloy stability but also promotes superior mechanical properties, particularly at elevated temperatures, as the high entropy hinders the movement of dislocations-the primary mechanism of plastic deformation-resulting in increased strength and ductility. The broadened compositional landscape further allows for tailored property design, opening possibilities beyond the limitations faced by traditional alloy systems.

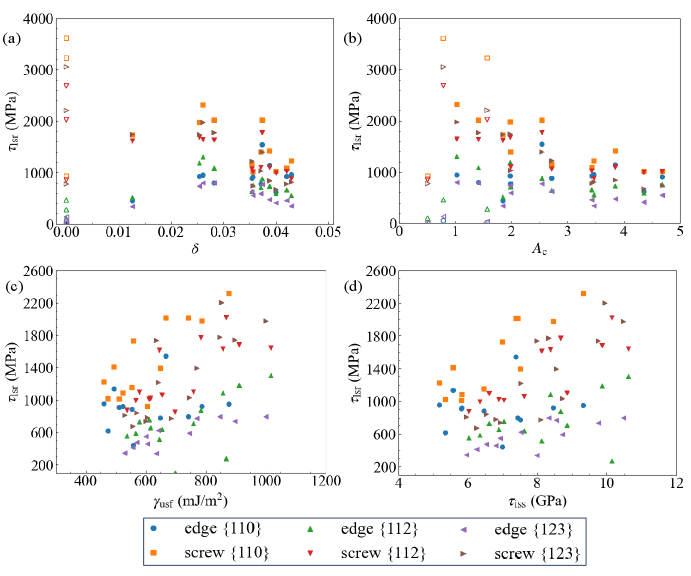

The creation of exceptionally strong yet ductile alloys hinges on a deliberate design strategy that introduces elements with a hexagonal close-packed (HCP) crystal structure into alloys primarily based on a body-centered cubic (BCC) structure – known as refractory multi-principal element alloys, or RMPEAs. Research demonstrates that exceeding 50% HCP element content significantly reduces both the Universal Slip Factor (USFE) – a measure of susceptibility to dislocation-mediated deformation – and the inherent stacking fault energy (ISS), thereby boosting the material’s resistance to fracture. However, this approach necessitates meticulous compositional control; imbalances can lead to the formation of brittle secondary phases, negating the intended strengthening effect and compromising overall performance. Consequently, the optimization of HCP element concentration within the BCC matrix presents a critical balance between maximizing strength and maintaining the alloy’s ability to deform without fracturing.

Dislocation Dynamics: The Microscopic Origins of Strength

Plastic deformation in metallic materials occurs through the collective movement of \text{Dislocation}s – linear crystalline defects within the material’s structure. These dislocations allow atoms to shift positions relative to one another with lower stresses than would be required to break and reform all the atomic bonds simultaneously. The movement isn’t typically a simple glide; it involves both glide (movement along the dislocation line) and climb (movement perpendicular to the glide plane, requiring vacancy diffusion). Dislocation density – the total length of dislocation line per unit volume – significantly impacts a material’s strength and ductility; higher densities generally lead to increased strength but reduced ductility. The ease with which dislocations move is determined by factors including temperature, stress, and the presence of obstacles within the crystal lattice.

Dislocation mobility, and thus a material’s yield strength, is directly impacted by interactions with imperfections in the crystal lattice. Solute atoms, differing in size and valence from the host atoms, introduce localized stress fields that either attract or repel dislocations. These interactions can effectively ‘pin’ dislocations, requiring increased applied stress to initiate plastic deformation. Similarly, other defects such as vacancies, interstitials, and precipitates act as obstacles to dislocation movement. The density and distribution of these defects determine the magnitude of strengthening achieved; higher defect densities generally correlate with increased yield strength, as dislocations must overcome a greater number of obstacles to move through the material. This interaction is the fundamental basis for alloy strengthening and work hardening mechanisms.

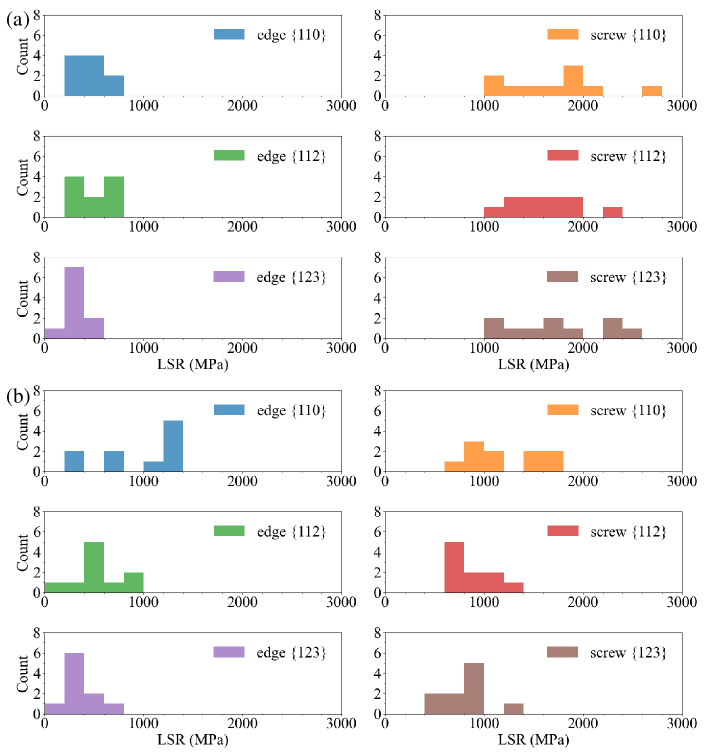

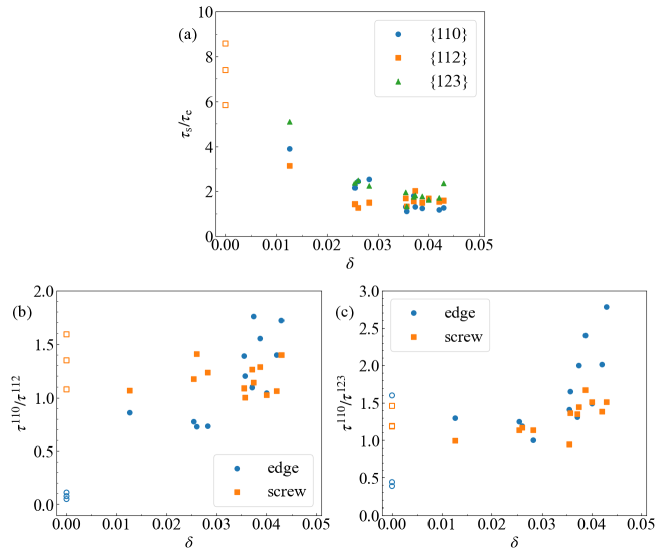

Detailed analysis of dislocation behavior within Body-Centered Cubic Refractory Metallic Powder Alloys (BCC RMPEA) is crucial for establishing the relationship between alloy composition and resulting mechanical properties. Specifically, characterization reveals that significant levels of Large Deformation (LD), quantified by a strain of δ greater than 0.03, lead to a demonstrable decrease in the screw-to-edge Local Segment Ratio (LSR). This reduction in the screw-to-edge LSR indicates a shift in dislocation substructure, impacting the alloy’s capacity to store energy during deformation and ultimately influencing its strength and ductility. Quantitative measurements of dislocation density, arrangement, and the screw/edge component ratio are therefore essential for predicting and tailoring the mechanical performance of these alloys.

Computational Modeling: Unveiling the Mechanisms of Deformation

Atomistic simulation, employing methods such as Molecular Dynamics and Density Functional Theory, allows for the calculation of fundamental material properties relevant to plastic deformation in Body-Centered Cubic (BCC) Refractory Medium- and High-Entropy Alloys (RMPEAs). These simulations model atomic-level interactions to predict dislocation behavior, including nucleation, glide, and interactions between defects. Specifically, researchers can determine critical resolved shear stress, stacking fault energies, and diffusion rates – properties directly influencing the mechanical response of RMPEAs. The technique enables the investigation of alloy compositions and microstructural features, providing insights inaccessible through purely experimental approaches, and facilitating the design of new materials with tailored properties.

Machine learning algorithms are increasingly utilized to process data generated from computational simulations of material deformation, specifically to establish relationships between local slip resistance (LSR) and intrinsic material properties. These techniques, including regression and neural networks, can analyze large datasets of LSR values – calculated from simulations tracking dislocation movement – alongside corresponding microstructural features such as grain size, solute concentration, and stacking fault energy. The resulting models enable the prediction of LSR based on material characteristics, and can identify key microstructural parameters that most significantly influence plastic deformation behavior. This approach allows for the efficient screening of alloy compositions and the optimization of material design for improved mechanical performance, exceeding the capabilities of traditional empirical methods.

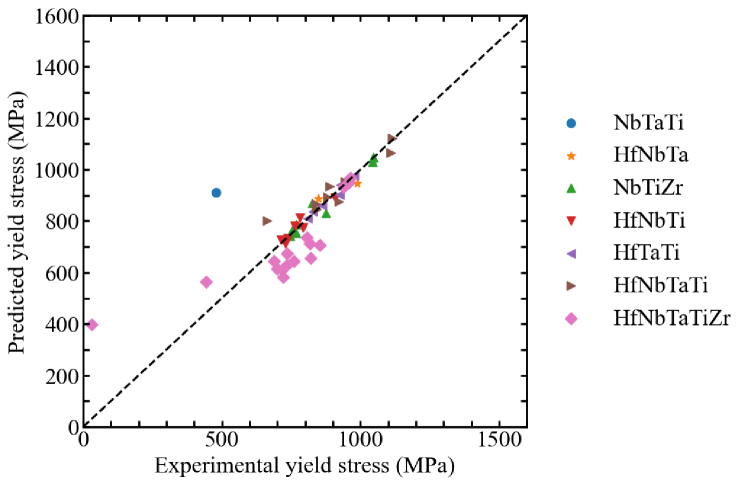

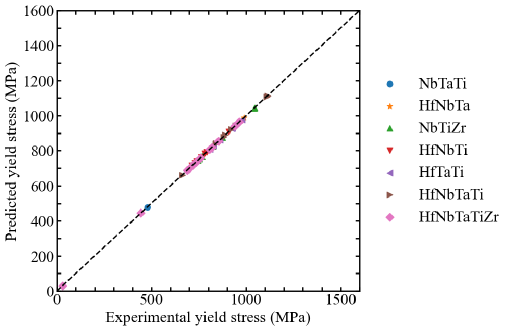

Computational modeling of BCC refractory medium-entropy alloys (RMPEA) allows for the isolation and quantification of the effects of compositional and microstructural features on plastic deformation mechanisms. By simulating deformation processes at the atomic scale, researchers can determine how variations in alloy composition – including the types and concentrations of constituent elements – and microstructure – such as grain size, dislocation density, and the presence of precipitates – influence slip resistance and overall mechanical behavior. Critically, predictions derived from these simulations demonstrate high correlation with experimentally observed mechanical properties, including yield strength, work hardening rates, and fracture behavior, thereby validating the computational approach and enhancing confidence in its predictive capabilities for material design.

Predicting Yield Strength: A Framework Rooted in Thermal Activation

A novel framework predicts the yield strength of refractory medium-entropy principal alloy systems by directly modeling dislocation behavior as a thermally activated process. This approach moves beyond empirical correlations and instead focuses on the fundamental mechanisms governing plastic deformation, recognizing that dislocations – line defects within the material’s structure – are the primary carriers of this deformation. The model accounts for how temperature influences the ease with which dislocations move – higher temperatures provide more energy for them to overcome obstacles – and how strain rate impacts their ability to propagate. By mathematically describing these thermally activated processes, researchers can now accurately predict how a material will yield under different conditions, offering a powerful tool for materials design and optimization. The resulting predictions demonstrate strong agreement with experimental data, enabling the development of RMPEAs tailored for high-performance applications.

The predictive power of this thermally activated model stems from its detailed consideration of factors governing dislocation movement within RMPEAs. Dislocation mobility, and consequently yield strength, is profoundly affected by temperature; higher temperatures facilitate easier dislocation glide and climb, reducing resistance to deformation. Conversely, increasing the strain rate – the speed at which a material is deformed – restricts the time available for dislocations to overcome obstacles, enhancing strength. Critically, the model also incorporates grain size, recognizing the Hall-Petch relationship where smaller grains present more barriers to dislocation motion, thereby increasing yield strength; the observed Hall-Petch coefficient K_{HP} consistently falls between 150.30 and 186.23 MPa⋅μm-0.5, demonstrating the model’s accuracy in capturing this fundamental material behavior.

The development of high-performance, room-temperature medium-entropy alloy (RMPEA) components is now significantly streamlined through a predictive framework for yield strength. This capability allows engineers to rapidly assess material suitability for demanding applications – from aerospace components to advanced tooling – without extensive physical testing. The framework’s accuracy, evidenced by a Hall-Petch coefficient (KHP) consistently ranging between 150.30 and 186.23 MPa \cdot \mu m^{-0.5}, enables a targeted approach to alloy design, optimizing grain size and composition to achieve specific mechanical properties. Consequently, material development cycles are shortened and the realization of novel, high-strength RMPEAs is accelerated, fostering innovation across a broad spectrum of engineering disciplines.

The study of refractory multi-principal element alloys reveals a fundamental truth: systems, even those engineered for resilience, are subject to the relentless pressures of time and material stress. Each instance of dislocation glide, each measurement of local slip resistance, represents a signal from time, indicating the evolving state of the alloy’s structure. As the research meticulously maps thermally activated yield strength, it acknowledges the inherent decay within the material-a decay that, through precise modeling and machine learning, can be understood and, to a degree, mitigated. Stephen Hawking observed, “However, if you are a physicist, you should know that time is relative.” This echoes the work’s focus; the ‘time’ of material failure isn’t fixed, but a variable influenced by atomic-scale phenomena and meticulously refined through data-driven insights.

What’s Next?

The presented work isolates local slip resistance as a crucial determinant of yield strength in complex alloys-a necessary, though not sufficient, step toward rational materials design. The inherent limitation, as always, lies in the translation of atomistic insight to macroscopic behavior. The current framework, while incorporating thermally activated processes, still treats the alloy as a relatively static entity. Time, however, is not a metric to be minimized, but the medium in which defects accumulate and systems evolve. Future iterations must embrace the transient nature of materials-the creep, the fatigue, the subtle shifts in lattice structure that ultimately dictate lifespan.

The reliance on machine learning, while effective for navigating the compositional space, introduces another layer of abstraction. Models are, by definition, incomplete representations of reality. The true test will be the ability to predict not just initial yield strength, but also the alloy’s degradation profile-how slip resistance changes under sustained stress and temperature. Incidents-the formation of dislocations, the onset of creep-are not failures, but steps toward maturity, revealing the inherent weaknesses within the alloy’s architecture.

Ultimately, the field requires a shift from seeking “ideal” materials to understanding the graceful degradation of all materials. The challenge isn’t to eliminate slip, but to manage it-to design alloys that fail predictably, reliably, and only after a prolonged period of service. The pursuit of perfection is a distraction; the art lies in accepting-and engineering-impermanence.

Original article: https://arxiv.org/pdf/2602.04827.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- God Of War: Sons Of Sparta – Interactive Map

- Poppy Playtime Chapter 5: Engineering Workshop Locker Keypad Code Guide

- Poppy Playtime 5: Battery Locations & Locker Code for Huggy Escape Room

- Poppy Playtime Chapter 5: Emoji Keypad Code in Conditioning

- Someone Made a SNES-Like Version of Super Mario Bros. Wonder, and You Can Play it for Free

- Who Is the Information Broker in The Sims 4?

- Why Aave is Making Waves with $1B in Tokenized Assets – You Won’t Believe This!

- One Piece Chapter 1175 Preview, Release Date, And What To Expect

- Overwatch is Nerfing One of Its New Heroes From Reign of Talon Season 1

- How to Unlock & Visit Town Square in Cookie Run: Kingdom

2026-02-06 05:11